What can a building technologist do about climate change? Part 3

WELCOME BACK

If you’ve stuck with me this long, thank you! You must be just as much of a buildings / climate change geek as I am.

Earlier, I wrote about about the need to address building related greenhouse gas emissions and discussed the frictions that I believe prevent residents from evolving their Personal Infrastructure.

However, there are three things that still feel unresolved in this current query: (1) Examples of current solutions (namely: startups) in the Personal Infrastructure landscape, (2) Approaches to interfaces as a smart tactic, and (3) Approaches to organizational structure as a critical foundation. The following explores these ideas; albeit in disjointed fashion.

The Personal Infrastructure landscape

Before we dig into interfaces and org structure– what is the current landscape of Personal Infrastructure?

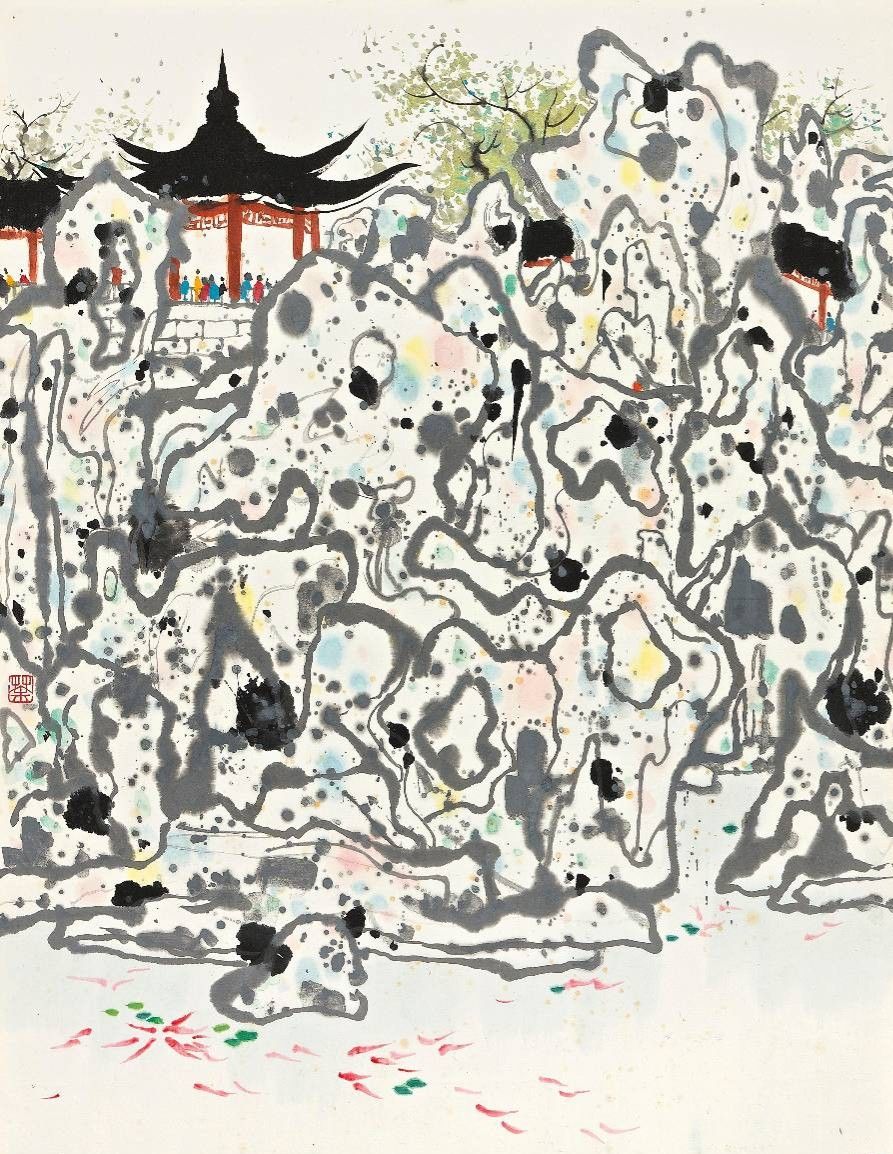

I’ll continue to update this with new versions, but a visual diagram of players can be seen here:

This list seems too short; who am I missing?!

Approaches to interfaces

In our Point A to Point B example from earlier, from an emission-ful to emission-less home, I said that there was a lot of grey area regarding pathways from A to B. What is the cause of this grey area? In addition to the general opacity of consumer awareness, the key issue in my opinion is distribution and maintenance. What are the interfaces for installation, operation, and maintenance of emission-less Personal Infrastructure?

Interfaces for Personal Infrastructure span both process (who does what and in what order) and product (design criteria and technical specs). Process interfaces include the relationship between tenant and landlord, interfaces with contractor gatekeepers of various size and expertise, and interfaces for financing (e.g. what data sets to support what anticipated bound of risks). Product interfaces include actual hardware and/or software technical specs, form factor, and translation protocols, environmental vs. introduced interfaces, and the juxtaposition of existing vs. new.

We also know from work by researchers like D Sheffer or D Hall that innovations in the building industry are more successful when either (a) they are adopted with full buy in from the owner, or (b) the innovations are modular, not requiring changes to existing process or product interfaces.

Why does owner vision matter? Ultimately, this comes down to systemic control. A system that answers to a single directive call ultimately moves in the same direction. Such is the benefit of centralized factories over decentralized, bid-led construction projects. Note: While helpful, I don’t think owner vision makes addressing interfaces any easier per se; the owner typically just helps with activation energy at the beginning, not the ongoing kinetic energy.

Why does modularity matter? Modularity is the opposite of an integral or interface-laden relationship. Modularity is sneak-in, sneak-out; just don’t disturb the neighbors. If one’s goal is quickest path to a workable solution, modularity is likely your way there. It avoids addressing sticky issues like existing path dependency, unsuitable conditions (such as a lack of specific knowledge), and the people factor of change management. Modularity capitalizes on existing value chains and power structures. I’m not saying it’s your best path forward… I’m saying it’s likely the fastest.

My sense is that the most successful solutions in this arena will be modular systems for owners. Modularity for the speed, owners for the activation energy. (But don’t forget… “modular” is in the eye of the hierarchical system beholder. If your point of inquiry doesn’t seem very modular right now, look up the hierarchical chain to determine at what level the system starts to become nearly decomposable from those around it!)

Approaches to org structure

Organizational structure, in my opinion, is the single most overlooked impact to stress in a system. At any point, a load applies force to an area. New issues of complexity or uncertainty can challenge a team, at multiple points. Depending on the organizational structure, those points may be more or less able to deal with the stress. When distributed knowledge seems poor, often communication channels are to blame. When expectations aren’t met, often responsibility and ownership are the culprit. Compare this with strain (how far a team will deal with these forces), and you can ultimately determine point of fracture.

Similarly, organizational process knowledge is more critical in today’s buildings industry than individual process knowledge. When process knowledge is individualized, distinct people develop tacit understanding, internalizing processes that are hard to write down. (Read more about process knowledge in Dan Wang’s 2018 piece.) This greatly benefits them and enables them to bring prior knowledge to new projects. However, the downsides are that a company that relies on individual process knowledge will not be able to retain that expertise and understanding in-house. That process knowledge can be easily lost. Given long time frames of complex projects, companies in the buildings industry would be wise to focus on organizational process knowledge instead.

To conclude

So where does this 3-part series leave us? And to be real, where does this leave me?

- Addressing climate change must involve the buildings industry

- We don’t know how to continually evolve our personal infrastructure (i.e. home and personal transport) here in the United States. And we need to, to adapt to and reduce the impacts of climate change. Learning to evolve our personal infrastructure has merit and benefits beyond its climate punching weight

- The hidden frictions to evolving personal infrastructure that will need to be addressed are: (a) Building Codes– not discussed in this piece; but see Hal Harvey’s Designing Climate Solutions for more, and (b) the black box of distribution & maintenance

- To make progress, the black box of distribution & maintenance for end use systems needs MUCH more love regarding (a) awareness, transparency, and sexiness (i.e. who is having the conversational relationship about changing your water heater from natural gas to electric???), and (b) operations and maintenance, to deal with split incentive hurdles, contractor gatekeepers, and financing head-scratchers

- The most successful innovations will approach interfaces smartly (if only this was the definition of “smart” buildings!)… prioritizing owners & modularity as makes sense

- The most successful innovations start with organizational structure in mind

- In reality, making this shift just in the US will not be enough. What’s more important is the soft power that extends forwards and backwards to countries in Asia that will really matter– think China, India, Indonesia. For example: what happens as the “missing middle” of China adds space & water heaters to their apartments where district heating doesn’t exist? What happens as more can afford personal air conditioners?

And Now

Let’s think of where to start. Who these days has a stronghold with homeowners, is smart about the sequence of modularity vs. interface, is public-policy-seasoned to address building codes, has experience with the ongoing operation of systems within the home, and could extend that sexy allure to other countries around the world? Why, maybe… Amazon, Google, Airbnb, and Tesla…